December 16, 2014

Medical Device Curing Oven Reduces N2 Consumption

Looking to purchase several large inert gas curing ovens, a customer in the medical device market came to us with a custom request: reduce their nitrogen consumption to save them money.

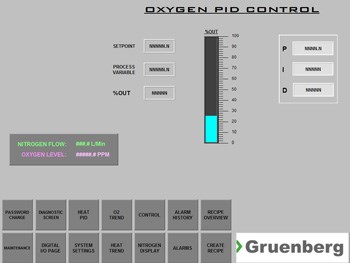

Our original device had a high volume purge. Once the minimum oxygen ppm was met, a continuous low flow of nitrogen would enter into the oven and continue to lower the ppm O2.

Engineers did some recalculations and had the idea to use a PID-based (Proportional Integral Derivative) control. The oven now operates on a nitrogen feedback loop. Sensors in the oven stop the flow of nitrogen when the oxygen ppm is at the required setpoint to enable the heating process to begin. As the process requires more nitrogen, the control opens up, and as the ppm drops, the amount of nitrogen is reduced. The new PID-based technology now reduces wasteful nitrogen consumption for a more efficient, high-performance oven.

Thermal Product Solution’s inert gas ovens are ideal for curing medical devices, because they prevent oxidation at elevated temperatures. Features like the impervious barrier between the process chamber and insulation material help to maintain the oven’s inert atmosphere and ensure process consistency. A wide variety of models are available, with temperature capabilities ranging from 60°F to 1200°F.