Out of Autoclave Curing Solutions from Gruenberg

TPS HAS THE EXPERIENCE, PROCESS AND TECHNOLOGY TO PROVIDE THERMAL CURING SOLUTIONS FOR AEROSPACE, ENERGY, AUTOMOTIVE, AND SPORTS PRODUCT COMPOSITE CURING APPLICATIONS.

GRUENBERG OUT OF AUTOCLAVE COMPOSITE CURING OVEN SOLUTIONS:

Strong, light-weight, and durable, components manufactured from advanced composite materials have revolutionized the aerospace, automotive, marine, infrastructure, construction, wind-energy, healthcare/medical, sports-products, and consumer-goods industries. Demand for these versatile materials will only continue to grow.

SOLUTIONS

VACUUM SYSTEMS FOR COMPOSITE CURING APPLICATIONS

Gruenberg offers a range of standard and optional vacuum technology for vacuum infusion processing; resin transfer molding (RTM); same qualified, resin transfer molding (SQRTM); vacuum assisted, resin transfer molding (VARTM); and prepreg processing.

Standard

Standard

- 8-port vacuum manifold, with ¼” MPT brass fittings

- hand-operated ball valves

- vacuum gauges

- ¾” MPT vacuum-system connection point

Optional

- 18.4 CFM Vacuum Pump, with 40 Torr (0.05 bar), with resin filter

- 30-Gallon Vacuum Receiver Tank to help mitigate vacuum fluctuations at individual ports, as other ports are opened and closed

- 8 Solenoid Valves with Selector Switches (replaces hand-operated valves in the standard equipment.)

- Pressure Transducers for each port and on the main line to provide constant feedback on vacuum levels

- Thermocouple Jack Panel on the interior of the oven to provide thermocouple hookups

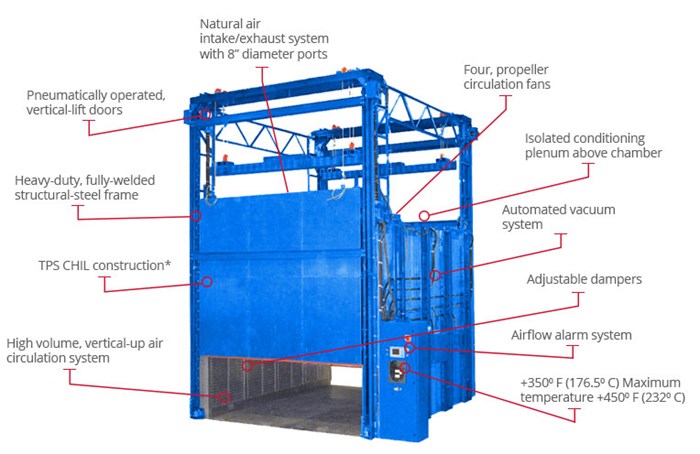

GRUENBERG CUSTOM OUT-OF-AUTOCLAVE OVEN IN ACTION

- Cures composite materials of complex contours, shapes and sizes, with little-to-no void content

- Cures advanced composite materials such as carbon fibers, ceramics, Kevlar®, Nomex®, thermoset, thermoplastic resins, epoxies, araminds, glass fibers, and nano-materials

- Economical operation with energy efficient, quick cycle times.

- Excellent temperature uniformity and precisely controlled airflow

- Standard and custom sizes to fit any workspace and accommodate any application

- Cures composite materials of complex contours, shapes and sizes, with little-to-no void content

- Cures advanced composite materials such as carbon fibers, ceramics, Kevlar®, Nomex®, thermoset, thermoplastic resins, epoxies, araminds, glass fibers, and nano-materials

- Economical operation with energy efficient, quick cycle times.

- Excellent temperature uniformity and precisely controlled airflow

- Standard and custom sizes to fit any workspace and accommodate any application

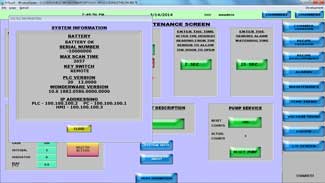

THE GRUENBERG FOCUS THERMAL PROCESSING CONTROL SYSTEM

Choose from three levels of control systems to meet your composite-curing needs –

APPLICATIONS FOR OUT OF AUTOCLAVE COMPOSITE CURING OVENS

AEROSPACE

AUTOMOTIVE

MARINE

WIND ENERGY

INFRASTRUCTURE/ CONSTRUCTION

HEALTHCARE/MEDICAL DEVICES

SPORTS PRODUCTS

CONSUMER GOODS

EXPERTISE IN COMPOSITES CURING OVENS

The TPS Composites Team has the expertise, systems, process, and technology to provide the innovative, customized solutions you need for the Out-of-Autoclave curing of composite materials. Our standard and custom products are backed by:

- Decades of experience with thermal-processing applications

- Customer access to our expert TPS Engineering Design Services (EDS) team

- Proof of concept and proof of process

- Development of test platforms and prototype units

- Finite analysis and simulation design

- Optimization of production processes

TPS COMPOSITES TEAM

Our expert team of engineers, technicians, and product specialists is here to help you select your custom composite-curing solution. Contact a member of our Composites Team to find the cure that’s right for you.