Thermal Product Solutions, a global manufacturer of thermal-processing equipment, announced the shipment of five (5) Tenney Vacuum Drying Ovens to a medical device manufacturer. The chambers will be used for vacuum drying of suture material.

These vacuum ovens have temperature ratings of +15° C above ambient to +60° C and work chamber dimensions of 24.125” W x 24.5” D x 24.125” H. The pressure range is sire level to 200,000 feet (0.169 mm Hg).

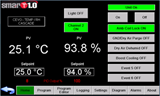

The chambers utilize temperature limited heating cables that are evenly spaced on the exterior of the pressure vessel. These cables are covered with thermal mastic for optimal heat transfer. The heating of these vacuum drying ovens will be controlled via the main controller. There is no cooling on this system.

“At TPS, we apply our expertise, experience and resources to create the best products for our customers. These vacuum ovens utilize a combination of fiberglass and polyurethane insulation surrounds the chambers to maximize the insulating characteristics and maximize temperature uniformity.” – John Eldred

Unique features of these Tenney vacuum ovens include:

All main power circuits shall have overcurrent protection

Busch DP0080A dry screw style pump

Nitrogen back fill connection with a control solenoid valve

Stainless Steel removable shelves

Allen Bradley remote Flex I/O electrical control system

#113819